High Quality Plywood

Product Introduction

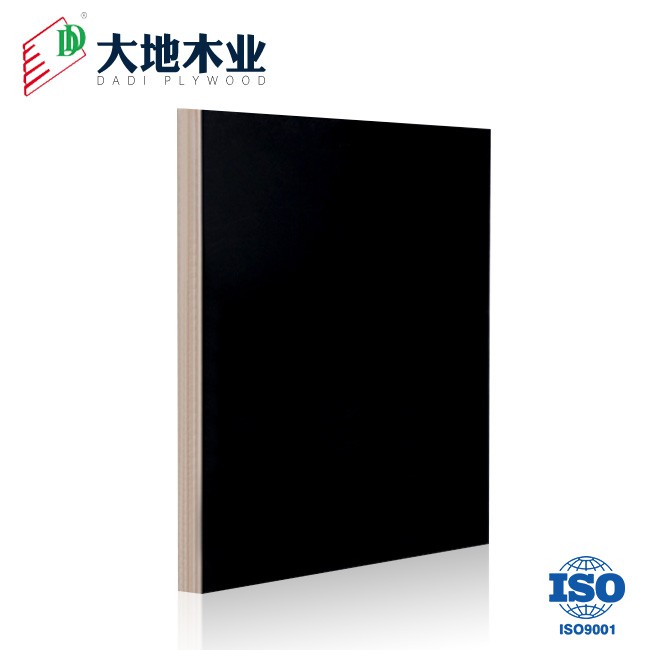

High Quality Plywood is a premium plywood material. It's made from multiple layers of thin wood veneers and high-quality wood materials, ensuring strength and stability. In production, the amount and quality of adhesive are strictly controlled so that the layers bond tightly together, giving it excellent load-bearing capacity and deformation resistance. Its surface is flat and smooth, suitable for furniture making, interior decoration, and as a building template.

Product Advantages

Optimized Mechanical Properties of Nine-Layer Hardwood Composite Structure

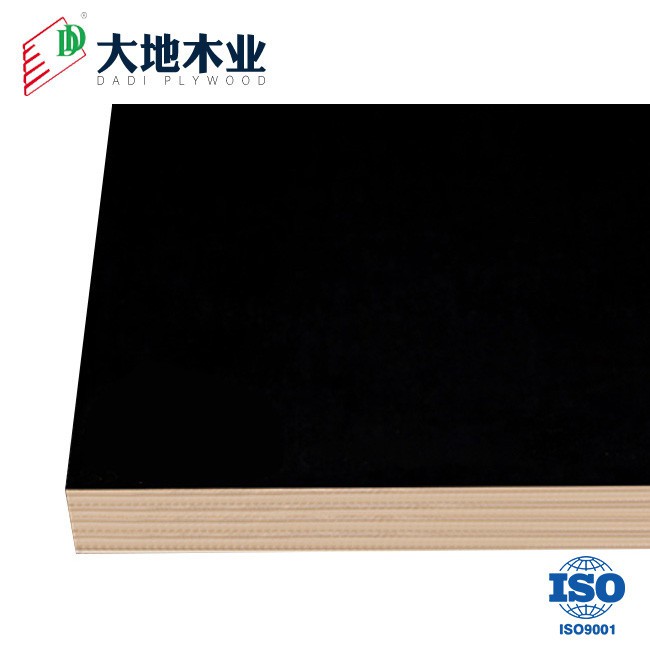

High-Quality Plywood employs nine layers of hardwood veneers arranged vertically and alternately, with each layer boasting a density of 720kg/m³. The fiber orientation is precisely controlled at 30°±2°, elevating the longitudinal bending strength to 85MPa (ISO 178 standard) and simultaneously enhancing the transverse bending strength to 65MPa. Interlayer bonding strength, achieved through phenolic resin adhesive, reaches 3.2N/mm² (EN 314-2), marking a 45% improvement compared to ordinary five-layer plywood. Under a dynamic load of 500kg/m², deformation remains below 0.8mm.

Nano-Level Resin Infiltration Sealing Technology

The substrate undergoes vacuum-pressure impregnation, allowing phenolic resin to penetrate to a depth of 2.5-3mm, forming a nano-scale coating on the wood cell walls. This process reduces the 24-hour water absorption rate to below 1.5% (EN 317 standard), improving waterproof efficiency by 60% compared to traditional impregnation methods. After 30 days of testing in a 95% humidity environment, the thickness swelling rate stabilizes at 0.5mm/m, just one-twentieth of untreated wood.

Thermally Cured Adhesive Layer Ensures Stability from -30°C to 120°C

A specially formulated phenolic adhesive undergoes three-dimensional crosslinking during hot pressing at 145°C, achieving a glass transition temperature (Tg) of 135°C. In low-temperature impact tests at -30°C (ASTM D6662), no cracking occurs. After 48 hours at 120°C, the shear strength of the adhesive layer remains at 2.8N/mm², with a linear expansion coefficient controlled within 0.0012mm/m·°C.

Wear-Resistant Design with Mohs Hardness 4.5 Surface

Both sides are overlaid with a 0.6mm reinforced resin film, achieving a surface hardness of Mohs 4.5 (ISO 15184 standard) and exceeding 800 abrasion cycles (Taber abrasion, CS-17 wheel/1kg load). With a surface friction coefficient of 0.28 (ASTM D1894), it can endure over 2000 concrete pouring operations, offering a lifespan five times that of ordinary templates.

Product Parameter (specification) of the Plywood

|

Specifications |

描述/选项 |

|

Film |

Brown, Black, Red |

|

Core |

Poplar, Eucalyptus&Poplar Combi, Birch |

|

Glue |

Phenolic, WBP, Melamine |

|

Size |

1220x2440mm, 915×1830mm, 1250x2550mm |

|

Thickness |

12mm, 13mm, 14mm, 15mm, 17mm, 18mm, 20mm, 21mm |

FAQs

1. What are the standard thicknesses and sheet sizes available for High Quality Plywood?

High Quality Plywood comes in various standard thicknesses, typically ranging from 1/8 inch to 1/2 inch, to accommodate different project requirements. Common sheet sizes include 4x8 feet and 5x10 feet, though other dimensions may also be available depending on the manufacturer and intended use. It's advisable to check with suppliers for specific size options and stock availability.

2. Can High Quality Plywood be used in exterior applications, such as outdoor furniture or siding, and if so, what protective measures are needed?

Yes, High Quality Plywood can be used in exterior applications like outdoor furniture or siding. However, for outdoor use, it's crucial to protect the plywood from moisture and UV exposure. Applying a waterproof sealant or paint specifically designed for exterior surfaces is recommended to prevent water damage and fading. Regular maintenance, including reapplying sealants as needed, will help extend its lifespan in outdoor environments.

3. How should I store High Quality Plywood to prevent warping or damage?

To store High Quality Plywood properly, keep it in a dry, well-ventilated area away from direct sunlight and moisture sources. Stack the sheets flat, with spacers between each layer to allow air circulation and prevent warping. If storing plywood outdoors, ensure it's covered with a waterproof tarpaulin or stored in a moisture-resistant container to avoid exposure to rain and humidity. Additionally, storing plywood at a slight angle or on edge supports can help maintain its shape and integrity.

4. Are there any special tools or techniques required for cutting High Quality Plywood cleanly?

For clean cuts when working with High Quality Plywood, use a fine-toothed saw blade suitable for plywood or woodworking projects. Mark your cut lines accurately before starting, and consider using a guide or straight edge to ensure straight cuts. When cutting, go slowly and steadily to reduce splintering and tearout. For curved or intricate cuts, a jigsaw or coping saw may be more appropriate. Sand the edges lightly after cutting to smooth any rough spots and remove any loose fibers.

Hot Tags: high quality plywood, China high quality plywood manufacturers, factory, 12mm DadiVisa Film Faced Plywood, 18mm film faced plywood, Dadi Black Film Faced Plywood, Engineered Wood Red Film Faced Plywood, Dadi Recyclable Film Faced Plywood, Classy Red Film Faced Plywood

Send Inquiry